“Horse hair furniture is a bit of a misnomer, since the high-end upholstery industry has almost uniformly replaced the actual horse hair used to pad furniture with a nylon synthetic ‘hair’ that outlasts its namesake” explains Joe Calagna, the 3rd generation upholstery master who with his sister Lana own Anthony Lawrence-Belfair in NYC’s tony Flatiron district. I spent an hour and a half with him yesterday to be educated on why his furniture is the very best available. Here’s what I observed and learned.

ALB is a staggeringly large workroom, encompassing 3 floors of a loft building for a total of 45,000 square feet, and employs 86 upholsterers, wood workers, seamstresses, and tailors. The company produces 100 pieces of bespoke furniture on average per month using centuries old methods passed down by generations of artisans. Apprentices taken on here are arduously trained for a decade before they are considered masters of their craft. A finished piece begins in a design conception meetings with any one of New York’s upper echelon interior designers, and ends with the last stitches of a hand closed cushion; every step executed slowly, methodically and with time-piece precision. Calagna took me on a guided tour of the manufacturing process of a sofa, which costs on average $1500 per running foot, so that I might share why this uber-pricy seating (he calls the Rolls-Royce of sofas) is worth the cost.

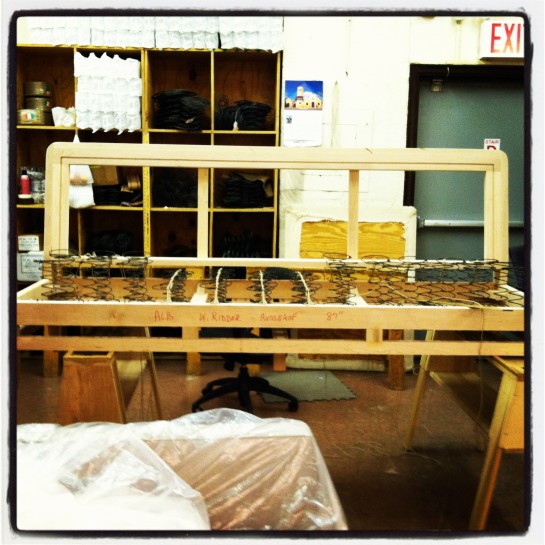

It all begins with kiln dried clear maple, the only wood ever used for frame construction at ALB. After carefully considering the exact finished dimension of a sofa, draftsmen labor side by side with carpenters to produce the skeleton of the piece. The frame components are carefully dowel joined with corner blocks meticulously added for strength. Exposed legs are stained and varnished, then wrapped for protection. The frame is brought to the main upholstery workroom, where a series of consecutive layers are added. First, jute webbing is affixed to the undercarriage in a basket weave pattern as the base of the seat support, with steel coil springs subsequently attached to the webbing. The springs are then hand tied (4 ways as opposed to 8, which produces a subtle give to the finished seat) with spun jute twine. The sofa in the snapshot I took below is at this stage of production.

Springs for the back of the sofa are attached and tied in the same fashion, and covered with ‘sack’, an upholstery burlap used between layers of construction. The next phase is by far the most time-consuming and requires incredible expertise to achieve successfully, the nylon hair. One hand full at a time the frame is slowly padded. Here the upholstery master’s eye, and an understanding of the hair itself (only gained by years of experience) bring the silhouette of the finished sofa to life. More sack covers the hair and is carefully basted onto the sofa so the hair padding doesn’t shift. This step takes days to complete versus the mere hours it would take a lesser quality workroom to spray glue foam padding in place. Next, cotton batting is meticulously laid on top of the basted sack, preparing the sofa for its muslin cover, often called the ‘under-upholstery’. At ALB, the muslin cover gives Calagna, the designer, and his craftsmen the opportunity to see the finished product before a scissor is taken to decorative fabric, a chance to consider any adjustments. This extra step is skipped by all but the best workrooms because it doubles the time and labor required in the actual upholstery process.

With the infrastructure complete, a team of cutters and seamstresses work carefully with the upholsterer to fashion the puzzle pieces of fabric to be carefully tacked in place. Extreme care is taken with COM (customer’s own material) fabrics, the cost of which can easily be thousands of dollars. The adage “measure twice, cut once” is the rule here. First the deck (base of the frame under the cushions) is upholstered, followed by the arms, and the inside back. Welting or trim is applied as specified by the designer. Finally the outside arms, then the outside back are slowly fitted and hand sewn in place with a curved needle and a running blind stitch. For a master upholsterer, the understanding of how to handle any and all fabric becomes second nature through time and experience. Cotton chintz requires radically different consideration than wool mohair. The staff here have that experience. Finally, there are the cushions to produce. In more commercial workrooms, foam is the base for cushions, often covered in feather wraps to create the illusion of down. Within 5 years the foam begins to oxidize and break down becoming uncomfortable and saggy. For 90% of the furniture made here, Calagna uses 100% goose down, the very best material for comfort and longevity. He concedes that down cushions require maintenance, they need to be “fluffed” to return to their original shape once you’ve stood up, but the comfort level while seated is unsurpassed.

A sofa manufactured at Anthony Lawrence-Belfair is meant to last a lifetime, manufactured by a team with more than 2500 years of collective experience. The absolute best quality materials used by the absolute best artisans to produce heirloom furniture. Yes it’s expensive, but the finest things in life always are.